Newly designed single horizontal impregnating and drying production line is used to continuously impregnate, dry and cut decorative paper, insulation paper(wood pulp) in line of wood-based panel.

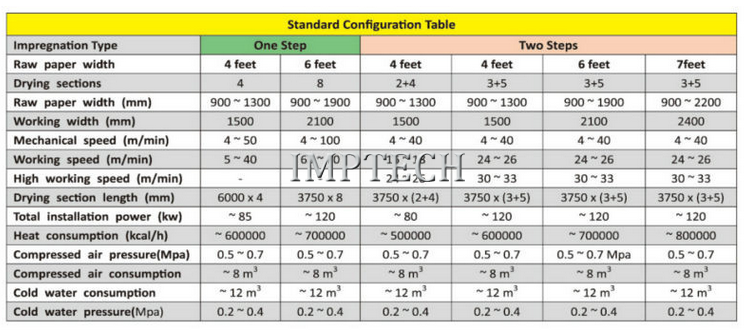

Technical Data of Paper Impregnation line of Hydraulic Press Machine:

Features

1. It has industrial standard modularized design, handy human-computer dialog and rich information reminder in

Chinese and English.

2. The high precision gauging roller ensures the gluing precision and surface quality of the impregnator.;

3. The high precision reticular roller(gravure coater) with precision scrubber secures the preciseness of glue coating;

4. The advanced and reliable tension control system works effectively in controlling the strain of the paper tape

operation;

5. Both the transmission roller and the hot-air blower come with high efficient energy saving inverter control to

reach low energy consumption, synchronous linear stability and low paper breakage;

6. The double photoelectric synchronous motor controls and adjusts deviation to have the deviation adjustment

stability and the stead operation of paper;

7. The paper cutter is available with the coding technology of preciseness and accurateness and being capable

of setting the cutting length at will;

8. The temperature of the drying chamber comes with PID high-precise control and the exact-accurate

temperature control;

Technical Parameters

1. | Main raw material | 28-170g/cbm |

2 | Max work width | 1850mm |

3 | Mechanical speed | 0-50m/min (frequency control and adjustable) |

4 | Width of roller surface | 2200mm |

5 | Diameter of paper reel | ≤1000mm |

6 | Weight of Paper reel | max 2000kg |

7 | Paper core diameter | 76mm |

8 | Impregnating material | UF/MF/PF |

9 | Glue quantity | 50%-270% |

10 | Volatilization content | 6.0%-7.5% |

11 | Production speed | decided by glue type and paper density |

12 | noise: | 80DB(A) |

13 | working height of paper: | 1200mm |

14 | Heat mode | thermal oil |

15 | Work temperature: | 100-180℃(by technology request) |

16 | overall size | About 57000mmX3500mmX4200mm (Length ×Width ×Height ) |

17 | total weight | about 65 ton |

18 | total power: | about 75Kw |

19 | Heat consumption | ≤800,000 Kcal/h |

20 | Compressed air: | 0.6MPa,5m3/h |

21 | Cooling water | 6 m3/h, 20℃, 0.4 MPa |

22 | Gluing precision: | ≤±2% |

23 | Volatility precision: | ≤±0.2% |

24 | Temperature control precision: | ≤±2°C |

25 | Length error of cutting final paper | ±1mm |

26 | Power supply: | 380VAC 50Hz |

Our service

Pre-sale service:

1) Free consultation on any aspect of equipment/production line;

2) The professional materials & flow chart;

3) Offering the reasonable plan & proposal as per customer's specific requirements;

4) Related reception for equipment inspection;

In-sale service:

1) Oversea equipment installation & commissioning;

2) Personnel training;

After-sale service:

1) 24 hours online service;

2) Video for equipment maintenance;

3) One year quality warranty;